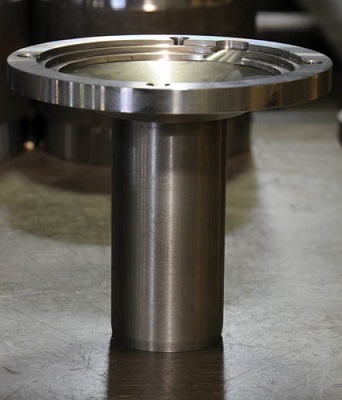

CNC Turning Services

Our advanced two-axis, CNC turning equipment comes equipped with magazine bar feeders that can work with material diameters measuring up to 1.25 inches. In addition, our CNC turning machinery can chuck parts up to twelve inches between centers.

Our CNC turning operations can work with a variety of substances all while upholding a tight ±0.001 of an inch precision tolerance. From the manufacturing of machine and engine components to fasteners, spindles, and shafts, our CNC turning services have successfully assisted multiple industries, including aerospace, architectural, and electronic. Contact Mechanical Designs of Virginia today to learn more about our advanced CNC turning capabilities.

Portfolios

CNC Turning Specifications

- Industry Focus

-

Aerospace

Agricultural

Architectural

Auto/Truck/Transportation

Chemical

Dental

Electronic

Food

Machine Tool

MarineMedical

Military

Mining

Oil Field

Optical

Packaging/Converting

Pharmaceutical

Railroad

Semiconductor

Signage

- Intended Applications

-

Machine components

Engine components

Turbine components

Hydraulic components

Turbo machinery components

Construction equipment

Shafts

Forgings

ValvesPins

Thread rod

Fasteners

Spindles

Sockets

Bushings

Spacers

Fittings

Standoffs

- Tolerances

-

Straightness : ± 0.001

Concentricity: ± 0.001Diameter (outer/inner): ± 0.001 in

Length: ± 0.001 in

- Part Diameter

-

Production Max

1.25 inChucking Max

12 in

- Part Length

-

Production Max

12 inChucking Max

12 in

- Machining Processes

-

Parting/Cutting

Facing

Turning:- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

Threading:

- External

- Internal

Knurling

Boring

Drilling

Counter boring

Countersinking

Pocketing

Profiling

Reaming

Tapping

Thread Milling

- Equipment

-

Lathe

- CNC

- Manual

- Equipment Capabilities

-

CNC Control Capabilities

Large Swing Lathe

Bar Feed

MillingCAD Design Services

CAM Programming Services

Reverse Engineering

- Machinery Axis

-

2

- Production Volume

-

Specialty Production Shop

Prototype

Low Volume

Small RunHigh Volume

Large Run

Long Run

Large Scale Production Volume Run

- Lead Times Available

-

Quoted on job by job basis

Emergency services availableRush Services Available

Ready To Start Your Next Project

MDV prides itself on its exemplary customer service and producing your parts to your exact specifications and the high degree of quality you demand.